Optimize your bioprocess with metabolomics and modeling

Combine time-resolved spent media analysis with metabolic models and process metadata to uncover metabolic bottlenecks, optimize media design, and significantly boost productivity through deep biochemical insights.

Optimizing productivity in biopharmaceutical manufacturing, for recombinant proteins, monoclonal antibodies, or other biologics, requires a deep understanding of how cells consume and respond to nutrients over time. Conventional tools like statistical design of experiments (DoE) can identify promising conditions, but they often miss the underlying metabolic reasons for success or failure. Metabolomics offers a window into nutrient utilization and secretion patterns. Simulating cellular metabolism with this data provides actionable recommendations for media and process optimization.

Our Capabilities

Time-course spent media analysis

Targeted profiling of nutrients from culture media provides precise, quantitative insights into how cells consume nutrients, secrete metabolites, and respond to their environment.

Dynamic flux balance analysis

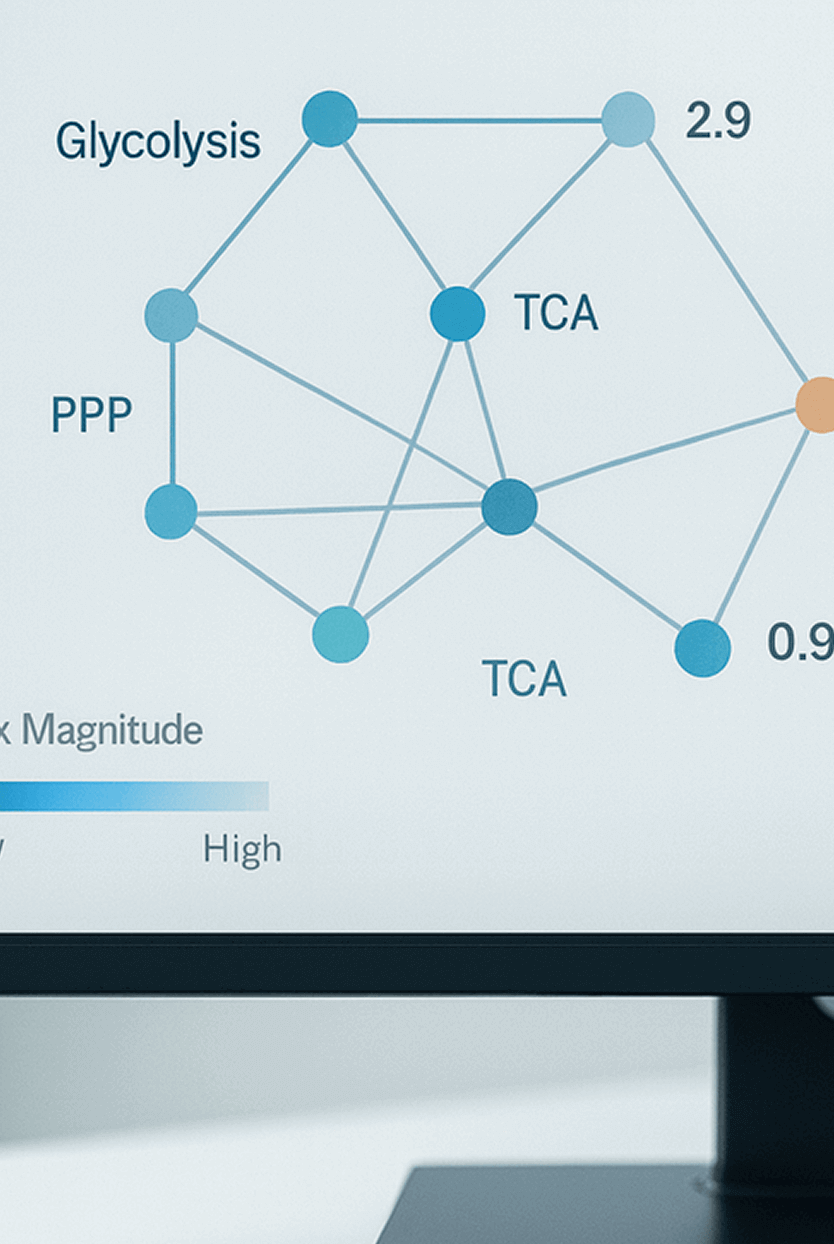

We simulate genome-scale metabolic model with nutrient uptake rates and process data to reconstruct a metabolic map with flux profiles across your process timeline. These identify when and where cells encounter limitations such as amino acid depletion or carbon overflow, and metabolic phase shifts.

Media and feed recipes

We suggest targeted data-driven modifications in your feed, media, and process parameters that you can implement easily.

Process integration

Within few iterations and experimental trials, you derive improved productivity, efficiency, and process consistency.

Ready to leverage metabolomics & modeling to design a productive process?

Connect with our scientists to discuss your process goals.